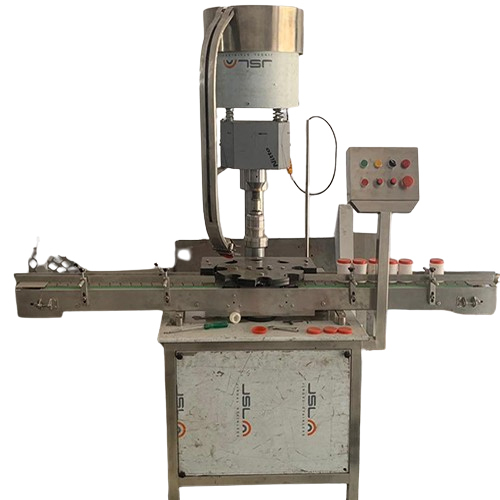

Automatic ROPP Bottle Capping Machine

Product Details:

- Type Pharmaceutical Packaging Machine

- Capacity 120 Pcs/min

- Computerized No

- Control Mode Automatic

- Voltage 220 Volt (v)

- Power 220 Volt (v)

- Weight (kg) 350 Kilograms (kg)

- Click to View more

Automatic ROPP Bottle Capping Machine Price And Quantity

- 230000 INR/Unit

- 2 Unit

- 370000.00 - 760000.00 INR/Unit

Automatic ROPP Bottle Capping Machine Product Specifications

- 1000x900x1600 Millimeter (mm)

- 220 Volt (v)

- 350 Kilograms (kg)

- Automatic

- Pharmaceutical Packaging Machine

- silver

- 220 Volt (v)

- 120 Pcs/min

- No

- 1 years

Automatic ROPP Bottle Capping Machine Trade Information

- Mundra

- Cash Advance (CA) Cash in Advance (CID)

- 3 Unit Per Month

- 20 Days

- Contact us for information regarding our sample policy

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

The aluminum capping machine epitomizes efficiency and precision in industrial packaging. Its automated design ensures a secure seal with aluminum caps, contributing to tamper-evident closures for various containers. Noteworthy for its adaptability, the machine effortlessly adjusts to accommodate different container sizes and cap specifications, guaranteeing a consistent and reliable seal without over-tightening or under-tightening. The integration of a cap feeding system streamlines operations, automating cap supply to the capping head for a continuous and efficient packaging line. Constructed from robust materials, these machines are built for durability, with safety features such as sensors to detect improperly capped containers ensuring product integrity. In industries like pharmaceuticals, food and beverage, cosmetics, and chemicals, aluminum capping machines play a crucial role in upholding the highest standards of packaging quality, exemplifying the fusion of cutting-edge technology and meticulous engineering in the service of seamless, precise, and secure packaging processes.

Introduction

In the competitive landscape of modern manufacturing, efficiency is paramount, and precision is non-negotiable. The packaging industry, in particular, demands cutting-edge technology to ensure secure and reliable product closures. The Automatic Bottle Capping Machine emerges as a technological marvel, promising not only the sealing of bottles but a transformative shift in the entire packaging process.

Understanding the Automatic Bottle Capping Machine

The Automatic Bottle Capping Machine is a state-of-the-art piece of equipment designed to revolutionize the process of sealing bottles. Its primary objective is to ensure a secure and precise closure while significantly enhancing the efficiency of the packaging line. This machine is an indispensable asset for industries dealing with beverages, pharmaceuticals, cosmetics, and other liquid products packaged in bottles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS