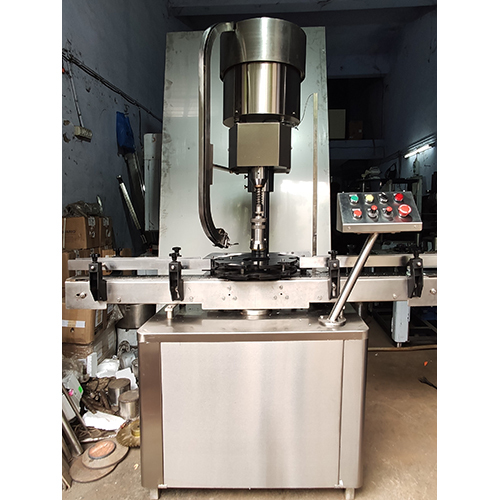

Automatic Bottle Crown Capping Machine

उत्पाद विवरण:

- टाइप करें

- क्षमता पीसीएस/मिन

- कम्प्यूटरीकृत

- कंट्रोल मोड

- वोल्टेज वोल्ट (v)

- पावर वोल्ट (v)

- वजन (किग्रा) किलोग्राम (kg)

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 2

उत्पाद की विशेषताएं

- पीसीएस/मिन

- मिलीमीटर (mm)

- वोल्ट (v)

- वोल्ट (v)

- silver

- 1 years

- किलोग्राम (kg)

व्यापार सूचना

- Mundra

- प्रति महीने

- दिन

उत्पाद वर्णन

An Automatic Crown Capping Machine is a device used in the bottling and packaging industry to securely seal bottles with metal crowns or caps. This type of Automatic Crown Capping Machine is commonly employed in the production of beverages such as beer, soft drinks, and certain types of bottled water. The crown cap is a metal cap with a cork or rubber liner on the inside that provides a tight seal to protect the contents of the bottle from external factors such as air and contaminants.

1. Feeding System

Bottles are typically fed into the machine using a conveyor system. The bottles move along the conveyor belt, positioning them for the capping process.

2. Cap Sorting and Feeding

Crown caps are loaded into a hopper or a cap sorting mechanism, where they are oriented in the correct position for placement onto the bottles. The caps are then fed to the capping station.

3. Capping Station

The capping station is the central part of the machine where the actual capping process takes place. The machine uses a mechanical or pneumatic system to apply downward pressure on the crown cap, forcing it onto the bottleneck and creating a secure seal.

4. Capping Heads

Automatic Crown Capping Machine can have multiple capping heads, especially in high-speed production lines. The number of capping heads depends on the machine's capacity and the production rate required.

5. Adjustability

These Automatic Crown Capping Machines often have adjustable settings to accommodate various bottle sizes and cap types. This flexibility allows manufacturers to use the same machine for different products.

6. Control System

Modern Automatic Crown Capping Machines are equipped with a control system that monitors and manages the capping process. This system may include sensors to detect improperly capped bottles and ensure that the capping heads are functioning correctly.

7. Safety Features

To ensure the safety of operators and prevent damage to the machine, Automatic Crown Capping Machines often incorporate safety features, such as emergency stop buttons and protective guards.

8. Material Handling

After the capping process, the sealed bottles are typically conveyed to the next stage of the production line for labeling, packaging, or further processing.

Automatic Crown Capping Machines contribute to the efficiency and reliability of the bottling process, ensuring that bottles are securely sealed before they are distributed to consumers. An Automatic Crown Capping Machine's specific features and capabilities can vary depending on the manufacturer and the intended application.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें